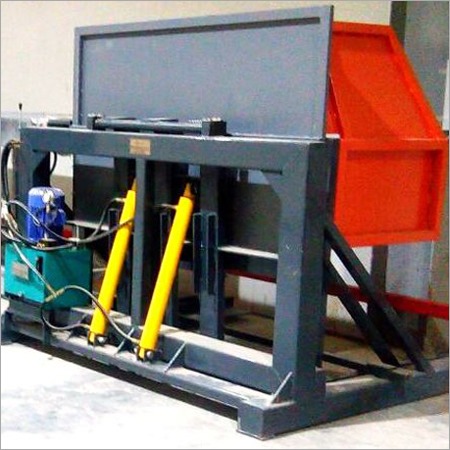

Box Tipper

MOQ : 1 Unit

Box Tipper Specification

- Shape

- Rectangular Body

- Features

- Easy Operation, Robust Construction, High Efficiency, Safety Interlocks

- Tool Type

- Tipper Machine

- Noise Level

- Low

- Usage & Applications

- For emptying/tipping bulk material from containers/boxes

- Product Type

- Box Tipper

- General Use

- Industrial Material Handling

- Capacity

- 500 Kg

- Weight (kg)

- 320 Kg

- Type

- Hydraulic Box Tipper

- Drive Type

- Electric Motor

- Power

- 1.5 HP

- Power Source

- Electric

- Transmission Type

- Gear Drive

- Start Method

- Push Button

- Machine Speed

- Variable (as per operation)

- Production Output

- Efficient Box Emptying

- Material

- Mild Steel

- Dimension (L*W*H)

- 1500 mm x 800 mm x 1200 mm

- Color

- Silver / Grey

- Cycle Time

- 40 seconds (approx.)

- Operating Voltage

- 230V AC

- Mobility

- Castor Wheels Provided

- Control System

- Panel Mounted Control

- Maximum Tipping Angle

- 120 Degrees

- Mounting

- Floor Mounted

- Surface Finish

- Powder Coated

- Service Support

- On-site & Remote

- Ambient Operation Temperature

- 0°C to 45°C

- Safety Features

- Interlock System, Emergency Stop Button

- Customisation

- Available for different box sizes

Box Tipper Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- Delhi

About Box Tipper

Highly acclaimed in the market, we manufacture and supply a wide range of Box Tipper. Stringently checked on various parameters before dispatching it to the clients, this tipper allows placement flexibility and saves floor space. Highly appreciated for its high operational fluency and excellent performance, this tipper is used for discharging the content of cartons or bins into feeders. Additionally, clients avail this Box Tipper from us in various technical specifications for their variegated needs.

Features:

- Easy to use

- Rust resistant finish

- Robust design

Reliable and Efficient Material Handling

The Box Tipper is designed for the industrial sector, enabling seamless emptying of bulk materials from various containers. Its hydraulic drive and gear transmission ensure high efficiency and swift operation, completing a cycle in approximately 40 seconds. The variable speed settings allow for flexibility as per your operational requirements.

Safety FirstIntegrated Interlock and Emergency Stop

Safety is at the core of this machines design. It comes equipped with an advanced interlock system and an accessible emergency stop button to minimize risk during operation. The powder-coated finish adds durability, ensuring both operator protection and low maintenance needs.

User-Friendly and Easily Customisable

With a panel-mounted control system and a straightforward push-button start, this box tipper is extremely easy to use. Castor wheels provide mobility despite its robust build, and customization options are available to cater to different box sizes to suit unique industrial applications.

FAQs of Box Tipper:

Q: How does the Box Tipper ensure safe operation during use?

A: The Box Tipper is equipped with safety interlocks and an emergency stop button, ensuring the machine stops immediately in case of any irregularities. Its robust construction and floor-mounted design enhance operational safety.Q: What is the maximum tipping angle and capacity of the machine?

A: This hydraulic box tipper can handle loads up to 500 kg, tipping materials at a maximum angle of 120 degrees for efficient and thorough emptying of containers.Q: When should the box tipper be used in industrial environments?

A: The machine is ideal for scenarios that require bulk material handling and fast emptying of containers, particularly in manufacturing, warehousing, and export facilities.Q: Where can the Box Tipper be installed and operated?

A: Designed for floor mounting, the tipper provides stability on industrial shop floors. Castor wheels allow it to be easily relocated within the facility as necessary.Q: What is the typical process for operating the Box Tipper?

A: Operation is initiated via a panel-mounted control system using a push button. The cycle takes approximately 40 seconds, with speed adjustments available as per your requirements.Q: How does customisation work for different box sizes?

A: The Box Tipper can be tailored to accommodate a variety of box dimensions. Manufacturers provide options to customise size specifications based on customer needs.Q: What are the main benefits of using this tipper machine?

A: The main benefits include improved efficiency in material handling, enhanced safety features, easy operation, low noise, and the ability to customise for a range of container sizes. Service support is available both on-site and remotely.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS