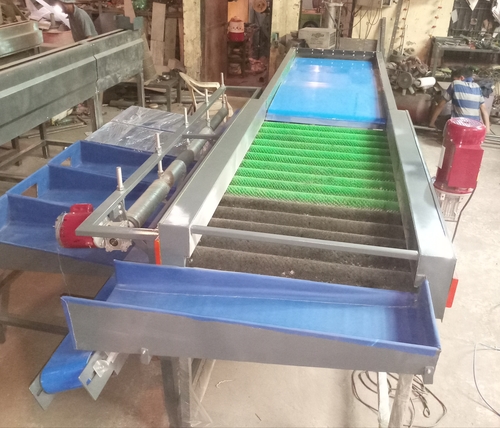

Automatic Mango Grading Machine

Price 250000.0 INR/ Piece

Automatic Mango Grading Machine Specification

- Power Source

- Electric

- Operating Temperature

- 5C to 40C

- Speed Mode

- Variable Speed

- Machine Type

- Fruit Grader

- Phase

- Three Phase

- Noise Level

- < 65 dB

- Feeding System

- Automatic Conveyor Belt

- Automation Grade

- Automatic

- Function Type

- Grading by Weight & Size

- Features

- Corrosion Resistant, Energy Efficient, User Friendly

- Frequency

- 50/60 Hz

- Product Type

- Fruit Grading Machine

- Material

- Stainless Steel

- Type

- Automatic Mango Grading Machine

- Capacity

- 2 to 5 Tons Per Hour

- Weight (kg)

- Approx. 1500 kg

- Product Shape

- Round / Oblong Mangoes

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based

- Installation Type

- Floor Mounted

- Voltage

- 220-440 V

- Power

- 2.5 kW

- Dimension (L*W*H)

- 5800 x 1500 x 1800 mm

- Raw Material

- Fresh Mangoes

- Feature

- High Precision Grading, Low Maintenance, Durable Construction

- Color

- Blue & Silver

Automatic Mango Grading Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 15-40 Days

About Automatic Mango Grading Machine

To effortlessly sort out varied mango we have Automatic Mango Grading Machine. This helps in dividing mangoes of different sizes, colors, shapes, weights and quality to pack in different lots. The bifurcation of the mangoes helps in packaging and selling at different markets. The machine is inbuilt with inspection unit, weighing line, feeding unit, belt conveyors and so on for performing its function. The major application of this machine is done to save time and indulge less staff for the same work. Our Automatic Mango Grading Machine is simple to install and operate and is highly durable.

Product Details:

| Material | Steel |

| Application | Agricultural Industry |

| Use | For Grading Mango |

Exceptional Grading Precision

Engineered to deliver over 98% accuracy in sorting, the machine utilizes a PLC-based control system and digital adjustment to ensure mangoes are classified precisely by weight and size. This technological advancement minimizes errors and optimizes pack efficiency.

User-Friendly and Safe Operation

Convenient handling is guaranteed with features such as an automatic conveyor feeding system, digital display panel, overload protection, and emergency stop. The wheeled base provides ease of movement, while durable, corrosion-resistant materials improve reliability.

Effortless Maintenance and Cleaning

All machine parts exposed to mangos are constructed from stainless steel and are easily washable, allowing fast cleaning between batches. The floor-mounted design ensures stability, while energy-efficient components reduce operational costs.

FAQs of Automatic Mango Grading Machine:

Q: How does the Automatic Mango Grading Machine achieve precise grading?

A: The machine uses an advanced PLC-based computerized control system and digital grade adjustment, achieving over 98% grading accuracy by assessing each mangos weight and size as it passes along the food-grade PVC conveyor belt.Q: What types of mangoes can this machine process?

A: It is designed to accommodate both round and oblong shaped fresh mangoes, ensuring versatile applicability for a wide range of mango varieties commonly found in India.Q: When is it ideal to use the automatic grading machine?

A: This machine is best utilized during peak harvest periods or large-scale packing operations, where rapid, consistent grading of mangoes by exporters, manufacturers, or suppliers is essential to maintain quality and workflow.Q: Where can this machine be installed and operated?

A: The floor-mounted design makes it suitable for installation in fruit processing facilities, packing houses, or export centers requiring robust automatic grading solutions. Its wheeled base allows for flexible movement within the production space.Q: What steps are involved in cleaning and maintaining the grading machine?

A: Routine cleaning involves washing the easily removable stainless steel parts after each cycle. Maintenance is straightforward due to the machines durable construction and low-maintenance components, ensuring smooth operation with minimal downtime.Q: How does the safety system enhance operator protection during use?

A: Safety is prioritized through features like emergency stop buttons and overload protection, which prevent accidents and safeguard both the machine and personnel during operation.Q: What are the main benefits of using this automatic grading machine?

A: Key benefits include improved grading accuracy, high throughput capacity (up to 5 tons per hour), energy efficiency, durable corrosion-resistant materials, low maintenance requirements, and a user-friendly digital control interface.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fruit Grading Machines Category

Automatic Apple Grading Machines

Price 250000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic : Yes

Installation Type : Other, Floor Mounted

Control System : Other, PLC Controlled

Fruits Grading Machine

Price 320000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic : Yes

Installation Type : Other, Floor Mounted

Control System : PLC Control

Automatic Fruit Grading Machine

Price 250000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Automatic : Yes

Installation Type : Free Stand

Control System : Manual

Orange grading machine

Price 250000.00 INR / Piece

Minimum Order Quantity : 1 Number

Computerized : Yes

Automatic : Yes

Installation Type : Free Stand

Control System : PLC Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS